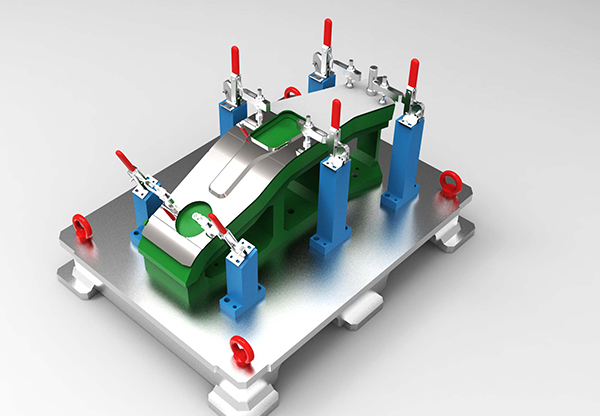

Figure 1 shows the design concept A with V shape. This concept designs were set to meet the gripping problem and cost effectiveness.

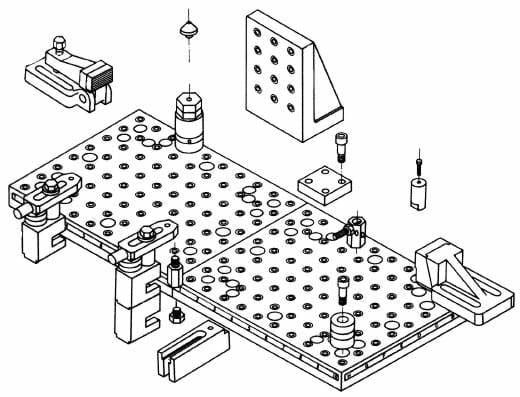

What Is Modular Fixturing Carr Lane

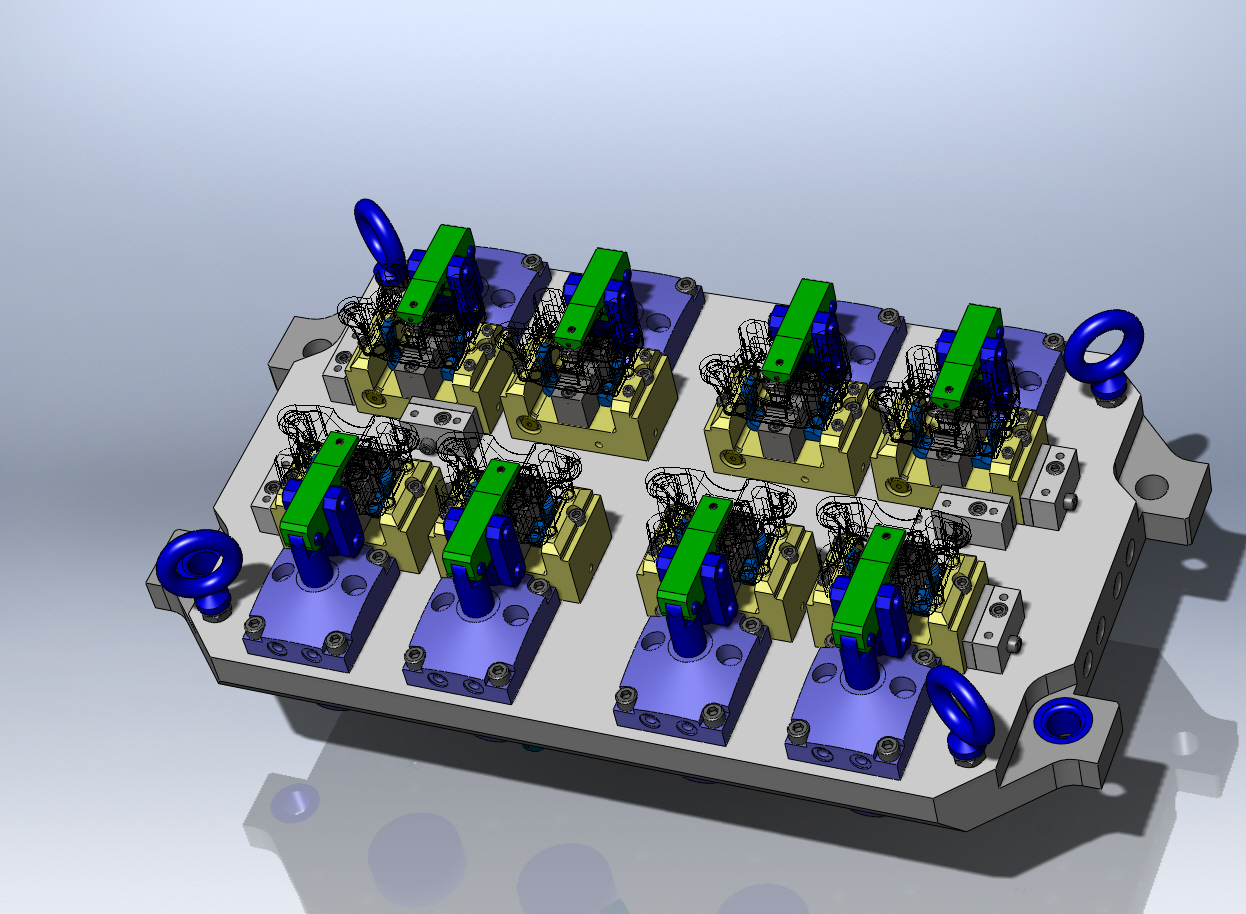

This paper on Design and manufacturing of 8 cylinder hydraulic fixture for boring YOKE on VMC 1050 which integrates all these aspects and the.

. A hydraulic fixture is designed for good manufacturability and assembly and proper fixture elements and hydraulic elements are selected. In most cases these benefits reduce costs for manufacturers allowing them to justify the initial investment for a hydraulic clamping system. Welding fixture design concepts pdf.

The Hydraulic Fixture is a tool for CNC machine and automated production lines as it allows work pieces to be positioned and clamped automatically. Deflection and von miss stresses are predicted by using ANSYS 172 software. The original fixture design is modified such that a total of eight threaded holes of diameter 22 mm is to accommodate the four l-blocks two l-1 blocks are placed on the surface of the fixture on one side while the other.

This paper on Design and manufacturing of 8 cylinder hydraulic fixture for boring YOKE on VMC 1050 which integrates all these aspects and the evolutionary functional approach of designed fixture is proved from the fact that a real industrial component is considered for fixture designing. Universal Valve Fixtures Combines the design concepts of both the C Frame and Modular Fixture into a Universal Valve Fixture. Except toggle clamp no other option is.

Fluid supply is an integral part of fixture design. In short the fixture is a tool that ensures correct and quick clamping or loading of the work piece with respect to the machine tool. Ad Serial or customized.

822 Basic PlanningHydraulic Design Hydraulic design is another critical design factor. This is the oldest most traditional method of supplying fluid to hydraulic clamps. Before manifold mounting using tubing was about the only option.

The following are the steps involved in assembling the individual components in creating the final concept and its working. Fixture design concepts pdf. Hydraulic clamping is based on and achieved here by isostatic pressure.

In machining fixtures minimizing workpiece deformation due to clamping and cutting forces is essential to maintain the machining accuracy. Supplying fluid to hydraulic fixtures is not merely an afterthought. The surface polishing reveals the rigid strength of the material.

The following Swing Clamp fixtures illustrate four distinct plumbing concepts. The flow rates must be high enough to clean the hole but not so high that circulating pressures in the tight annular space exceed the open hole fracture gradient. It is considered part of the house the apartment or building and therefore.

UNIT 4 DESIGN OF FIXTURE Design of Fixture Structure 41 Introduction Objectives 42 Design of Fixtures 43 Types of Fixture and its Industrial Application 431 Vise Fixture 432 Milling Fixture 433 Facing Fixture 434 Boring Fixture 435 Face Plate Fixture 436 Turning Fixture 437 Grinding Fixture 44 Summary 45 Key Words. In addition of the fixture being hydraulic type. The design parameters such as maximum deformation maximum shear stress number of contact faces and maximum.

The hole should be inclined at 45 degree angle with the surface. Ad Serial or customized. Fixture design concepts ppt.

Welding fixture design concepts. This component is a part of three wheeler auto. In addition to a hard-copy fixture design manual a procedural CD-ROMWeb-page for fixture design principles for.

Several design concepts were generated and simulated to analyze using ANSYS software. Hence a step-by-step procedure for jig and fixture design will be developed. For example you have a drill machine and want to make a 10mm diameter hole at the point of intersection of the two diagonals of a square plate.

Basic fixture design concepts. This paper includes the unique aspect of designing and manufacturing 5-cylinder hydraulic fixture for machining case of motor body on VMC EZ5 of pallet size 600 mm 400 mm. A device is personal property that becomes real property if connected to a structure or construction.

Oncept U shape with knurling. Model is developed in Creo 40. Remember me on this computer.

Figure 1 shows the design concept A with V shape. This concept designs were set to meet the gripping problem and cost effectiveness. Jon jincai zhang in applied petroleum geomechanics 2019.

What is Hydraulic Fixture. The recent trends in industry are towards adopting the hydraulic techniques because it save time generates. Co ept A V shape Figure 2 shows the desig o ept B U shape with knurling that has advantage such as better gripping and less energy consumed.

Fixture design for the sample part j cecil 2008 hydraulic system this paper proposes a polynomial fit based simulation method to build nonlinear model in hydraulic actuator control system. The present research work formalizes the use of hydraulics in. The hydraulic fixture is designed for Engine cylinder block to perform drilling and boring operations using Vertical machining centers.

This paper present design of hydraulic fixture for engine side. The main objective of this study is to propose a new design of jigs and fixtures for hydraulic press to carry out the gripping problem from existing design. Specific constraints for each shop will again be identified.

The operation to be performed is finishes milling of flange drilling reaming spot facing on VMC. This is basic equivalent circulating density ECD management. Hydraulically clamped fixtures have many advantages over manually clamped fixtures.

Oncept A V shape Figure 2 shows the design concept U shape with knurling that has advantage such as better gripping and less energy consumed. Hydraulic lift housing is. A clamping system that uses high-pressure liquids to power clamps and hold a work piece in place.

Log in with Facebook Log in with Google. Close Log In. Total equivalent stress of the structure is 9816 Nmm 2.

Computer aided fixture design of fixture assembly is carried out using CATIA V5 software and Finite element analysis of fixture and cylinder block is carried out using ANSYS Static workbench software. Tubing lines on top of fixture plate. Co ept B U shape with k urli g.

Of the concepts and methodologies of fixture design for Tinker will be developed. Several design concepts were generated and simulated to analyze using. Hydraulic fixture design concepts.

Hydraulic Fixture is major application in the field of designing where in several softwares are available for the purpose of design. Specifically designed and developed for use in the Valve Industry the fixture provides greater flexibility in covering a large range of valve bodies parts with a. From Simple Manual Fixtures To Hydraulic Fixtures.

Cnc Fixtures Automation Design Group Inc

New Royal Machine Tool Universal Modular Fixture Reduces Fixture Costs And Changeover Time By Eliminating Custom Work Nests And Top Jaws Royal Machine And Tool

Jigs And Fixture Design Edst E Learning

Fixture Design For The Sample Part J Cecil 2008 Download Scientific Diagram

Fixture Design Services Engineering Intrax

Kriatec E Learning About Course

Design Principles Of Jigs And Fixtures Prescient Technologies

0 comments

Post a Comment